(Toronto, Canada) — GRIP Metal has invented and launched a state-of-the-art building block ideal for small homes, affordable housing projects, emergency relief shelters, intensive care units and more. The new GRIP Block is a CLT (Timber Cross Laminated Block) that allows for quickly assembly and disassembly of structures while offering outstanding strength and durability.

“Affordability and environmental impact are two key concerns for home and commercial builders today, and GRIP delivers on both fronts,” said Mark Lavelle, Global Sales Director for GRIP Metal. “With its strength and versatility, the GRIP Block is the perfect solution for smaller homes, hospitals, shelters and more. It takes LEGOs to the next level.”

GRIP Metal recently collaborated with Toronto architect Tye Farrow to use the blocks’ technology to create easy-to-deploy ICU wards, which can readily be built and scaled for COVID-19 patients. Furthermore, the GRIP Strips used in construction are now being carried by Rothoblaas, the world’s largest timber company.

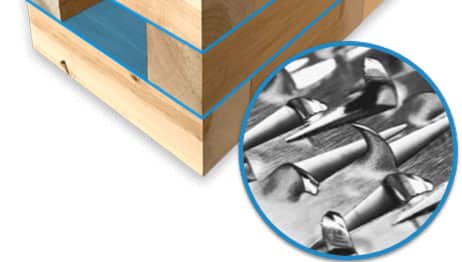

GRIP Block uses an innovative mechanical attachment technology in place of industrial adhesives to create an equally strong,lightweight and durable building material; it is comprised of layers of cross-laminated timber that are pressed into modules, which can be used for a variety of building purposes.

Similar to LEGO blocks that hook together, the GRIP Timber Cross Laminated Block makes it easy to construct strong, lightweight living and working structures without requiring skilled labor.

The blocks, which are similar in size but distinctly lighter than concrete block, include internal cavities for electrical and mechanical needs. They can integrate with GRIP Metal flooring, which provides in-floor heating and durability, in building projects.

About GRIP Metal:

Featuring precisely designed hooks that give designers, engineers and scientists a brand-new foundation for design and manufacture of complex forms in composites, GRIP Metal transfers the core strengths of a metal substrate to other materials. Consisting of a consistently shaped field of micro-scaled hooks that are formed onto ultra-thin gauge sheet metals, using robust mechanical adhesion to overcome the challenges of bonding different materials together. Potential applications range from strengthening thin-gauge composite materials in papers, woods and plastics, to large- scale use in construction technologies and materials. For more information, please visit https://www.gripmetal.com/.